Overview:

This machine adopts the new optimized

design, PLC automatic control, man-machine interface tracking,

positioning accuracy. Sub-package into the state, put an end to bottle,

inverted bottle, flexible adjustment, safety and beauty. Adjustable hot

air circulation structure, applicable to a variety of existing thermal

film (including color printing), film replacement quick and easy, fault

warning, stop lock complete, reliable operation. Which can be a constant

quality, smooth and reliable, long continuous production.

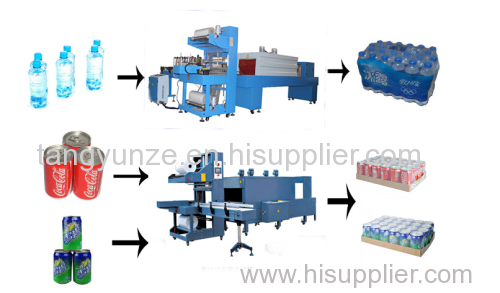

Applicable to the long objects or beverages, beer, mineral water, cans, glass bottles and with or without other paper care

Technical Parameters:

| Dimension for the whole unit | L5500mm ×W3200mm × H2100mm | Thermal shrinkage passage dimension | L1800mm × W650mm × H450mm | Max. package dimension | L600mm ×W400mm × H350mm | Transfer belt dimension | 10-15Pcs/minute | Packaging speed | 800-1200mm | Operating power supply/power | 0.5-1.5s 140℃-160℃ | Sealing and cut time/temperature | three-phase five-wire 380V 19kw | Operating air pressure | 0.6-0.8Mpa | Air consumption | 0.5m3/minute |

|

.jpg)